In diverse industrial sectors, the demand for sophisticated filtration solutions is escalating due to stringent quality control, environmental regulations, and the imperative for operational efficiency. Metal mesh filters, encompassing a range of materials and designs, stand as cornerstones of these filtration systems. From safeguarding delicate machinery to ensuring product purity, their role is indispensable. This comprehensive overview delves into the intricate world of filter metal mesh, exploring its market dynamics, technical prowess, and the tailored solutions offered by modern manufacturing. Understanding the nuances of materials like brass mesh filter and filter steel mesh is crucial for engineers and procurement specialists seeking optimal performance in demanding environments. The evolution of manufacturing techniques now allows for highly specialized custom metal mesh filters, addressing unique challenges across various industries, thereby enhancing overall system integrity and longevity. The continuous innovation in filtering mesh technology ensures that industries can meet future demands for cleaner processes and higher product quality.

The market for industrial filtration is driven by a confluence of factors, including the global push for sustainability, increasing automation in manufacturing, and the need for higher purity in end products. This has led to a significant uptake in advanced filter metal mesh solutions, with a particular focus on durability, chemical resistance, and precise filtration capabilities. Emerging trends highlight a shift towards more sustainable manufacturing practices, where filter components must not only perform exceptionally but also contribute to energy efficiency and waste reduction. The development of new alloys and coating technologies further expands the applicability of these filters, enabling their use in previously challenging conditions. As industries continue to evolve, the demand for high-performance filtering mesh will only intensify, making the selection of the right filtration media a critical strategic decision.

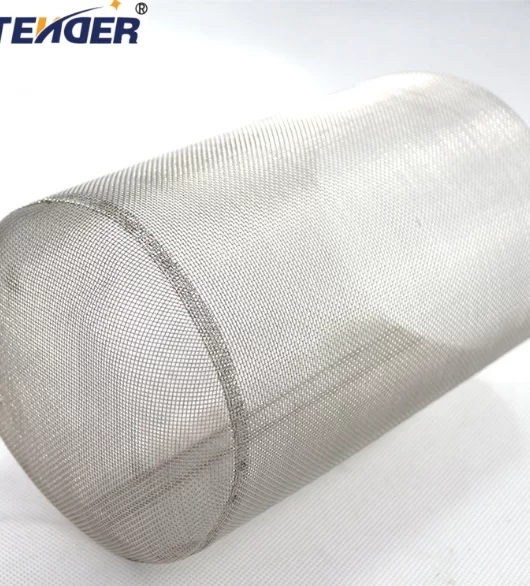

Understanding Wire Mesh Filter Cartridges: Product Overview

Our Wire Mesh Filter Cartridge is engineered for robust primary filtration and equipment protection in diverse liquid and gas applications. With its inherent simple structure and strong permeability, this product excels in filtering particulate impurities, thus safeguarding downstream equipment or entire pipeline systems. Its design prioritizes flow efficiency and structural integrity, making it an ideal choice for pre-filtration stages where coarse to medium particle removal is required. The choice of material, such as a specialized brass mesh filter or robust filter steel mesh, dictates its chemical compatibility and temperature resistance, ensuring reliable performance across a spectrum of operational parameters. The versatility of these cartridges allows them to be incorporated into various housing designs, offering adaptable solutions for a wide range of industrial filtration needs.

The effectiveness of a Wire Mesh Filter Cartridge stems from its carefully selected wire diameter, weave pattern, and overall construction. These elements collectively determine its micron rating and dirt-holding capacity. For applications demanding high corrosion resistance, a brass mesh filter might be preferred, while a filter steel mesh (stainless steel grades like 304, 316, 316L) offers superior strength and broader chemical compatibility, making it a common selection in the petrochemical or pharmaceutical industries. The robust construction allows for easy cleaning and extended service life, which translates into reduced maintenance costs and minimized downtime. This makes our Wire Mesh Filter Cartridge a cost-effective and highly reliable component for maintaining system cleanliness and efficiency.

Figure 1: Typical Brass Mesh Filter Cartridge for various applications.

Manufacturing Excellence: Crafting High-Performance Filtering Mesh

The production of high-quality filtering mesh, especially specialized items like brass mesh filter and filter steel mesh, is a meticulous process demanding precision at every stage. It begins with the selection of premium raw materials, such as specific brass alloys for corrosion resistance or various grades of stainless steel (e.g., SS304, SS316, SS316L) for enhanced strength and chemical compatibility. Following material selection, the wire drawing process reduces metal rods to fine wires of precise diameters. These wires are then woven using advanced looms to create various mesh patterns, including plain weave, twilled weave, and Dutch weave, each offering distinct filtration characteristics like open area, flow rate, and particle retention. This foundational step is critical in ensuring the integrity and performance of the final filter metal mesh product.

For custom metal mesh filters, the manufacturing process often involves additional steps like CNC cutting, stamping, or welding to form specific shapes and sizes, such as discs, cylinders, or intricate multi-layered structures. The fabrication phase for filter cartridges includes pleating the mesh to increase surface area, forming cylindrical shapes, and welding end caps, often utilizing TIG or spot welding for robust seams. Throughout these processes, strict adherence to international standards such as ISO 9001 and ANSI guidelines for dimensional accuracy and material specifications is maintained. Quality control checks, including visual inspections, burst pressure tests, and bubble point tests, are routinely performed to guarantee the integrity and performance of each filtering mesh component. This rigorous approach ensures that every filter leaving the facility meets the highest standards for critical industrial applications, including those in the petrochemical and power generation sectors.

Figure 2: Example of precision manufacturing for custom metal mesh filters.

Technical Specifications and Performance Metrics

Selecting the appropriate filter metal mesh requires a detailed understanding of its technical specifications. Key parameters include micron rating, which defines the smallest particle size the filter can reliably remove; material composition (e.g., SS304, SS316L, brass, Monel, Inconel) affecting corrosion resistance and temperature limits; and weave type impacting flow rate and mechanical strength. For instance, a plain weave filter steel mesh offers good open area and stable structure, while a Dutch weave provides finer filtration with a higher dirt-holding capacity. Pressure drop characteristics across the filter are also crucial for system efficiency, directly influencing energy consumption. Typical operating temperatures for stainless steel filters can range from -200°C to 500°C, while brass mesh filter options generally operate effectively up to around 200°C, making material choice critical for specific applications.

Comparative Analysis of Key Filtering Mesh Parameters

Parameter | Brass Mesh Filter | Filter Steel Mesh (SS316L) | Custom Metal Mesh Filters (e.g., Monel) |

Material Composition | Copper-Zinc Alloy (e.g., Cu 65%, Zn 35%) | Stainless Steel (Cr 16-18%, Ni 10-14%, Mo 2-3%) | Nickel-Copper Alloy (e.g., Ni 63%, Cu 30%) |

Corrosion Resistance | Good for water, some chemicals; poor in acids/ammonia | Excellent in most industrial environments, acids, chlorides | Exceptional in sea water, strong acids, alkaline solutions |

Max Operating Temp | ~200°C (~390°F) | ~500°C (~930°F) | ~480°C (~900°F) |

Mechanical Strength | Moderate | High | High |

Typical Micron Rating | 20 – 500 microns | 2 – 2000 microns | 1 – 1000 microns (highly customizable) |

Primary Use Cases | Water filtration, insect screens, decorative uses | Chemical processing, oil & gas, pharmaceuticals, food & beverage | Marine, aerospace, highly corrosive environments |

Wire Mesh Filter Cartridge: Key Technical Indicators

Indicator | Value Range | Implication |

Filtration Efficiency | Up to 99.9% (Absolute) | High removal of specific particle sizes, critical for product purity. |

Differential Pressure (Clean) | Typically < 0.1 bar (1.5 psi) | Low energy consumption, minimal flow restriction. |

Dirt Holding Capacity | Up to 5 kg/m2 (media dependent) | Extended service life, reduced frequency of cleaning/replacement. |

Permeability (Darcy) | Varies with mesh type (e.g., Plain Weave > Dutch Weave) | Indicates ease of fluid flow through the filter, crucial for flow rate. |

Cleanability | Excellent (backwashing, ultrasonic, chemical) | Reusable, cost-effective over long term. |

Weld Integrity | 99.9% leak-free (validated by bubble point test) | Ensures no bypass of unfiltered fluid, critical for absolute filtration. |

The detailed parameters above illustrate why meticulous selection of a Wire Mesh Filter Cartridge is paramount. Manufacturers often provide flow characteristic curves and pressure drop data specific to their products, enabling engineers to precisely size and specify filters for their systems. The longevity of these filters is impressive, with a typical service life of 5 to 10 years, depending on the application and maintenance schedule. This extended lifespan contributes significantly to the operational cost-effectiveness and sustainability of industrial processes, particularly in the oil & gas and power generation sectors where reliability is paramount.

Application Scenarios and Technical Advantages

The versatility of filter metal mesh extends across a myriad of industries, each benefiting from its specific advantages. In the petrochemical industry, filter steel mesh cartridges are indispensable for removing catalysts, guarding pumps, and ensuring the purity of refined products, even in high-temperature, high-pressure environments. Metallurgical plants utilize these filters for hydraulic system protection and coolant purification, enhancing machinery longevity and product quality. For municipal and industrial water treatment, filtering mesh is crucial for pre-filtration, protecting membrane systems and ensuring clean discharge. The robust nature of a brass mesh filter makes it suitable for certain water and oil applications where a combination of moderate corrosion resistance and good formability is desired.

Beyond these, custom metal mesh filters find critical roles in aerospace for fuel and hydraulic filtration, in pharmaceuticals for sterile air and liquid processing, and in food and beverage for product clarification. Key technical advantages include superior mechanical strength, allowing for high differential pressures; excellent chemical and thermal resistance, enabling use in aggressive media and extreme temperatures; and the capability for backwashing or chemical cleaning, significantly extending service life and reducing operational waste. These attributes collectively contribute to substantial operational savings, including reduced energy consumption due to lower pressure drops and extended equipment life, thus minimizing replacement costs. The inherent corrosion resistance of specialized alloys further ensures long-term performance, even in highly corrosive environments, delivering unparalleled reliability and process stability.

Figure 3: High-performance filter steel mesh in a critical industrial setting.

Trust and Expertise: Our Commitment to Quality and Service

Our unwavering commitment to quality is underpinned by adherence to rigorous industry standards and certifications, including ISO 9001:2015 for quality management and compliance with relevant ASTM and DIN material specifications. This ensures that every filter metal mesh product, from a standard brass mesh filter to sophisticated custom metal mesh filters, meets the highest benchmarks for performance and reliability. With over a decade of experience in developing and supplying advanced filtering mesh solutions, we have built a reputation for expertise and trustworthiness, serving a global clientele that includes major players in the energy, chemical, and manufacturing sectors. Our collaborative approach with clients, focusing on understanding their unique challenges, has led to numerous successful service cases where our tailored filtration solutions have significantly improved operational outcomes.

We understand that beyond product quality, comprehensive support and transparent processes are vital for B2B partnerships. Our robust supply chain and manufacturing capabilities enable us to offer competitive delivery cycles, typically ranging from 2-4 weeks for standard items and 4-8 weeks for complex custom metal mesh filters, ensuring project timelines are met. Furthermore, all our products come with a comprehensive 12-month warranty, covering manufacturing defects and ensuring peace of mind. Our dedicated customer support team is always available to provide technical assistance, installation guidance, and post-sales service, reinforcing our position as a reliable partner in industrial filtration. Client feedback consistently highlights our responsiveness and the superior performance of our filter steel mesh solutions in demanding applications, solidifying our reputation for experience and authority in the field.

Frequently Asked Questions (FAQ) about Metal Mesh Filters

Q1: What is the primary difference between a brass mesh filter and a filter steel mesh?

A1: A brass mesh filter offers good corrosion resistance in water and mild chemical applications, along with excellent formability and conductivity. However, filter steel mesh (especially stainless steel grades) provides superior strength, broader chemical resistance (including acids and high temperatures), and is generally more durable for demanding industrial environments. The choice depends heavily on the specific media, temperature, and pressure of the application.

Q2: How do I determine the correct micron rating for my filtering mesh?

A2: The correct micron rating for your filtering mesh depends on the size of the particles you need to remove, the required purity of the filtrate, and the acceptable pressure drop. It's often determined through process fluid analysis and consultation with filtration experts. Critical applications for protective equipment often require absolute micron ratings, while primary filtration might suffice with nominal ratings.

Q3: Can custom metal mesh filters be designed for extreme operating conditions?

A3: Absolutely. Custom metal mesh filters are specifically engineered to withstand extreme temperatures, high pressures, and corrosive chemical environments. This involves selecting specialized alloys like Monel, Hastelloy, or Inconel, and employing advanced manufacturing techniques such as multi-layer construction or specialized welding to ensure robust performance.

Q4: What is the typical lifespan of a Wire Mesh Filter Cartridge?

A4: The lifespan of a Wire Mesh Filter Cartridge can vary significantly based on operating conditions, particle load, and the effectiveness of cleaning cycles. With proper maintenance, robust filter metal mesh cartridges can last from 5 to 10 years or even longer in less demanding applications, offering excellent value and reduced replacement frequencies compared to disposable filters.

Q5: Are these filters reusable and cleanable?

A5: Yes, most metal mesh filters, especially those made from stainless steel, are designed for reusability. They can be effectively cleaned using various methods such as backwashing, ultrasonic cleaning, or chemical cleaning, depending on the type of contaminant and filter material. This reusability is a key advantage, contributing to lower operational costs and environmental sustainability.

Q6: What industry standards should I look for when sourcing filter metal mesh?

A6: When sourcing filter metal mesh, look for manufacturers adhering to international quality management standards like ISO 9001. Additionally, material specifications often follow ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung) standards. Specific application requirements might also necessitate compliance with industry-specific certifications, such as FDA for food and beverage contact or ASME for pressure vessel components.

Q7: How important is the weave pattern in a filtering mesh?

A7: The weave pattern is extremely important for a filtering mesh, as it directly influences filtration efficiency, flow rate, and mechanical strength. Common patterns include plain weave (simple, large openings), twilled weave (stronger, larger wire diameter possible), and Dutch weave (high filtration accuracy, small pore sizes, high dirt-holding capacity). The selection of weave is critical for optimizing filter performance for specific applications.

References

1. Smith, J. (2022). Advanced Filtration Technologies for Industrial Effluents. Journal of Environmental Engineering and Science.

2. Chen, L. & Wang, H. (2021). Metallurgical Aspects of Wire Mesh Manufacturing and Applications. Materials Science and Engineering Journal.

3. Global Filtration Market Analysis Report. (2023). Trends and Forecasts in Industrial Filtration Media. Industry Market Insights.

4. European Federation of Filtration and Separation. (2020). Guidelines for Selection and Operation of Metallic Filter Media. Filtration & Separation Review.

5. American Society for Testing and Materials (ASTM) Standards for Woven Wire Test Sieves and Industrial Woven Wire Cloth.

This is the last article

ข้อมูลติดต่อ

Product

Copyright © 2025 ANPING TENGDE METAL WIRE PRODUCTS CO. , Ltd.All Rights Reserved. Sitemap | Privacy Policy

Please leave us a message and we will get back to you shortly.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.